Warehouses are a silent partner in the global supply chain industry. With nondescript facades, these commercial buildings are typically associated with low tech services around the storage of raw materials and parts for manufacturing operations and distributions centers. Globalization and the continued growth of e-commerce have increased the need for manufacturers to outsource inventory management and supply chain services for warehouse, distribution, and order fulfillment. In the North American market, demand for value-added warehousing jumped 8% in 2018 to reach $43.3 billion. As package and shipping demands increase year over year, warehouse and logistics operators are adapting and innovating to stay competitive. Warehouse businesses worldwide have started to embrace warehouse automation. Let’s take a closer look at why it’s time for warehouse professionals to ride the automation wave when developing their warehousing strategy.

Increased Demand and Shrinking Demographics

Similar to the manufacturing industry, ongoing talent gaps in storage and logistics services has caused many companies to turn to technology for a solution. However, the issue is more than truck driver shortages or finding dedicated talent for labor-intensive hourly positions. Demographically, the aging workforce is leaving behind a labor pool too small to fill the demand. According to Datex estimates, 60 million Baby Boomers will retire in the coming years, but there are only 40 million Generation X candidates to replace them, and not all of them are qualified to fill necessary positions.

Customer demands have also evolved; customers now expect higher levels of service at a lower cost. Once a premium service, expedited shipping must now be offered as a standard option to stay competitive. Warehousing has become a high-tech big business with global names in retailing, manufacturing, and distribution. All these businesses are depending on the warehousing industry to grow in volume and technical complexity to meet the rigorous demands of globalization.

Value-Added Storage Solutions

Logistics companies have begun to address this need with value-added services that are turning traditional warehouses into light manufacturing operations. These services often include kitting and the conversion of subassemblies into finished goods, which reduces procurement, assembly, and receiving costs for manufacturers.

Due to the demand for quick conversions and same-day shipping, these are growing service segments. Kitting reduces purchasing and receiving time by condensing recurrent reorders with multiple parts to a single line item. Subassembly allows manufacturers to receive parts preassembled and organized, allowing them to spend less time assembling pieces in-house. Subassembly can include a host of services from measuring and cutting, custom labeling, product testing, and pre-mounting. These services help reduce labor costs and maximize floor space usage for manufacturers.

Upskilling the Workforce

The automated warehouse will require several traditional positions such as dockworkers and material handlers to expand their skill sets. Automation technology will help free up workers for new value-added subassembly and kitting services. It will take over previous roles that involved time-consuming tasks like product picking, packing, restocking, sorting, and loading inventory for shipment.

Warehouses will eventually need to be staffed by engineers and technicians with the ability to implement, operate, and repair complex machines. The automation of repetitive tasks gives existing workers the freedom to focus on kitting and subassembly, which bring a higher value-add to warehouse operations.

Warehouse Execution Systems

Warehouse Execution Systems (WES) are essential software platforms to manage the flow of products from receiving to shipping. for automation. A hybrid of warehouse control systems (WCS) and traditional warehouse management systems (WMS) it helps manage inventory and controls automated processes, order data, and program pick zone routing. Several companies provide this software alone with different consulting companies to help you decide the best solution for your needs as well as system integrators that can take over implementation and maintenance.

Enabling the Automated Warehouse

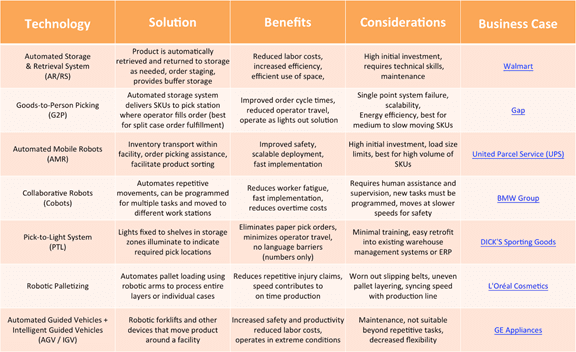

Conversations around the competitive benefits of automation are expanding as more companies adopt the technology. UPS recently announced the deployment of AMRs from Locus Robotics to optimize distribution center operations and enhance productivity. Companies like Omron have designed many self-guided mobile robotics solutions to help efficiently move products and materials around different work environments. Amazon has also utilized pick-to-light systems for automation. In this light-guided solution, storage zones illuminate to indicate required pick locations, which minimizes operator travel and increases accuracy.

Below is a table graphic showing some warehouse automation solutions already being adopted for warehouse operations:

Warehouses of the future will be able to handle more materials, provide more services, and operate with less labor. It is essential to approach all new automation initiatives with the SMART Goal framework to ensure objectives are Specific, Measurable, Achievable, Realistic, and Timely. Warehouse and logistics services looking to reduce overhead and increase efficiency may require different solutions than one with a skilled labor shortage. No single system can fully meet all the requirements of a fully realized warehouse automation system, but actions taken now will build the foundation for companies to achieve sustainability and growth post COVID-19.